LHL-DLT Series Electric Thermostatic Drying Oven: Precise Temp Control for Industrial & Lab Applications

For drying, wax melting and sterilization tasks across industrial enterprises, laboratories and scientific research units, the electric thermostatic drying oven delivers precise, uniform thermal processing with robust safety and programmable control to meet diverse operational needs

- modelLHL-DLT Series

- brandLABEKS

- min. order1 pcs

- packageplywood case package

description

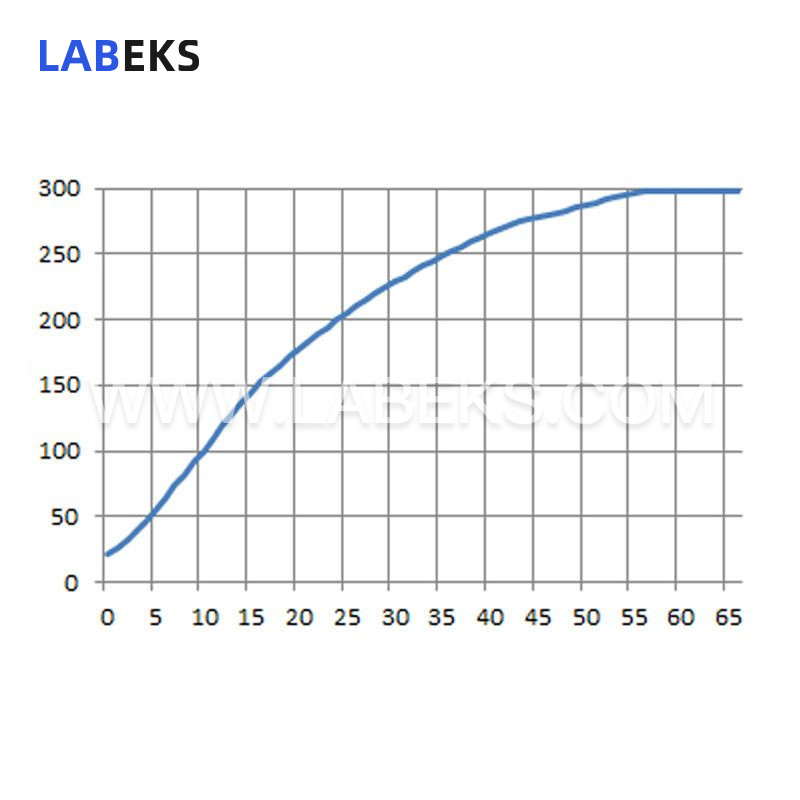

The LHL-DLT Series electric thermostatic drying oven is fitted with an LCD multi-data operation display, integrating power failure memory, compensation functionality, and overheating alarm and prevention systems. Its operating temperature ranges from room temperature +10 to 300°C, with PID-based precise temperature control ensuring exceptional temperature distribution accuracy of ±3.0%. For T-type models, the LCD touchscreen program controller can store up to 50 experimental programs, enabling seamless mutual conversion between single-stage temperature control and programmed temperature control.

Available in volumes of 30L, 45L, 65L, 85L, and 125L, this series is designed to satisfy a variety of operational requirements.

features

1. The self-developed digital display over-temperature preventer makes temperature control more accurate, stable, safe and reliable.

2. Equipped with an L-type LCD multi-data full-screen operation display featuring power failure memory and compensation; the T-type LCD touchscreen program controller can store 50 experimental programs, with single-stage temperature control and program temperature control available for mutual conversion.

3. Boasts high precision, high efficiency, excellent safety and a wide operating range.

4. Insulated door technology keeps the outer door surface at low temperature and prevents deformation during high-temperature operation.

5. Pull-out tray partition design allows for quick and convenient sample placement and retrieval.

6. Enables easy operation with fixed-value operation, timing operation and automatic stop functions.

7. Dedicated function keys facilitate straightforward temperature setting.

8. The auxiliary menu supports over-temperature alarm, deviation correction, and menu lock functions.

9. Includes overheating alarm, menu lock, and overheating prevention protections.

specifications

Model | Digital type(D) | LHL-30D | LHL-45D | LHL-65D | LHL-85D | LHL-125D |

|---|---|---|---|---|---|---|

Liquid crystal type(L) | LHL-30L | LHL-45L | LHL-65L | LHL-85L | LHL-125L | |

Touch screen type(T) | LHL-30T | LHL-45T | LHL-65T | LHL-85T | LHL-125T | |

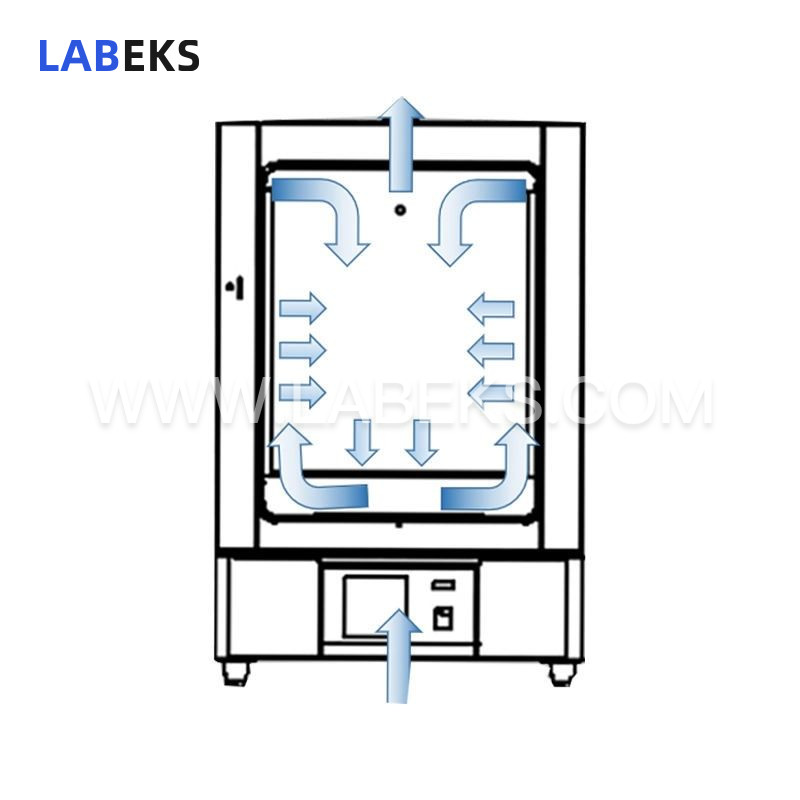

Mode | Natural convection | |||||

Performance | Temp. range | RT+10~300℃ | ||||

Temp. resolution | 0.1℃ | |||||

Temp. fluctuation | +-1℃ | |||||

Temp. distribution | +-3.0% | |||||

Constitution | Interior | mirror stainless steel plate | ||||

Exterior | cold-rolled steel plate, surface coating with chemical resistance | |||||

Thermal insulation material | aluminum silicate fiber | |||||

Heater | Ni-Cr alloy heating wire OCr27AL7Mo2 | |||||

Rated power | 0.8kw | 1.0kw | 1.5kw | 2.0kw | 2.5kw | |

Exhaust port | I.D. 28mm*1, top | |||||

Controller | Temp control mode | D-type: digital tube dual-row PID L-type:LCD dual row PID T-type:5 inch color touch screen fuzzy PID | ||||

Temp setting method | D/L-type: Tap four buttons to set T-type:Touch screen setting | |||||

Temp display method | D-type: Measuring temp display: 4-digit digital upper ; Set temp display: 4-digit digital lower | |||||

L-type: Measuring temp display: LCD upper; Set temp display: LCD lower | ||||||

T-type: Measuring temp display: Touch screen upper; Set temp display: Touch screen lower | ||||||

Timer | 0-9999 minutes ((with timing wait function) | |||||

Running function | fixed value running, timing running, automatic stop | |||||

Program mode | D/L-type:optional,T-type:Single-stage temp control and program tempcontrol can be interchanged; store 50 experimental programs, each program canbe set with 50 steps, each step can be set for 0-6000 minutes, adjustable | |||||

Additional functions | deviation correction, menu button lock, power failure compensation, powerfailure memory(L/T-type:prevent overheating) | |||||

Sensor | Pt100 | |||||

Safety device | over-rise prevention (D-type:optional,L/T-type:standard) | |||||

SPEC | Internal dimensions(W*L*Hmm) | 310*310*310 | 350*350*350 | 400*360*450 | 450*450*450 | 500*450*550 |

External dimensions(W*L*Hmm) | 428*505*710 | 468*538*753 | 518*550*860 | 567*640*853 | 617*639*953 | |

Outer packaging size(W*L*Hmm) | 552*578*840 | 592*618*880 | 642*628*980 | 692*718*980 | 742*718*1080 | |

Internal volume | 30L | 45L | 65L | 85L | 125L | |

Partition bearing capacity | 15kg | |||||

Partition layers | 5 layers | 6 layers | 8 layers | 8 layers | 11 layers | |

Space between partitions | 40mm | |||||

Power supply(50/60Hz)rated current | AC220/3.6A | AC220/5.5A | AC220/7.2A | AC220/8.2A | AC220/10.5A | |

Net weight/Gross weight kg | 32/37 | 37/43 | 43/49 | 49/55 | 62/68 | |

Accessories | Partition | 2 pieces | ||||

Configuration that can be added | Partition, RS485 interface, printer, recorder, external communication,remote control, program temperature controller, wireless SMS alarm, U diskdata storage | |||||

why choose us

Premium Quality with CE & ISO

We conduct 100% performance testing on every unit, ensuring its stable operation and superior performance in your application.

24/7 Expert Technical Support

Our senior engineers are on standby 24/7, ready to provide expert solutions at any time to minimize your operational downtime.

20+ Years R&D & Production

Our deep technical expertise is your solid guarantee for professional and reliable OEM/ODM services.

Trusted in 80+ Countries

Industry leaders and research institutions in over 80 countries and regions rely on our equipment for stable operation.

True Manufacturer, Factory-Direct Price

Bypass the middlemen to get our factory pricing and speak directly with our core engineers.

Rapid & Reliable Delivery

Our extensive in-stock inventory provides a solid guarantee for rapid and reliable global delivery.

Our Factory

20 Years

58 Experts

20000 m²

7X24 Hours