LGP-DLT Series Dual-Use Lab Dry Oven & Incubator with Uniform Temp for Research & Production

Designed for universities, labs and production facilities, this dual-use dry oven & incubator eliminates all microorganisms via oxidative cell protoplast destruction within specified heating periods.

- modelLGP-DLT Series

- brandLABEKS

- min. order1 pcs

- packageplywood case package

description

Boasting exceptional quality, reliability and operational safety, the LGP-DLT Series dual-use culture/drying box employs forced air convection via its integrated cover. It is widely utilized across universities, research institutions and production facilities.

features

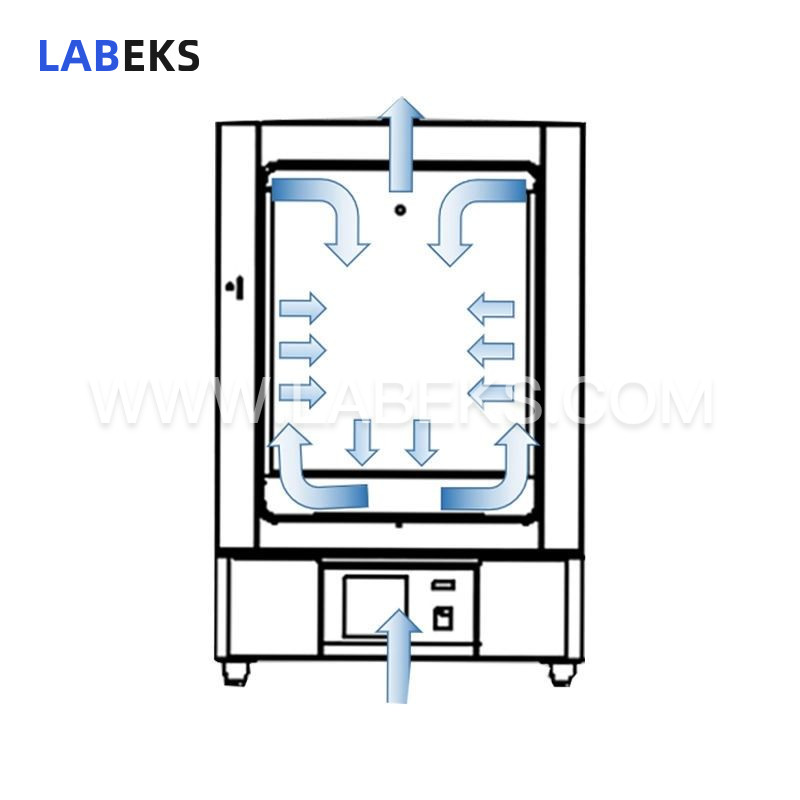

Centrifugal turbine-driven forced air supply ensures highly uniform temperature distribution throughout the chamber

Auxiliary menu provides over-temperature alarm, temperature deviation correction and menu locking functions

Offers high precision, efficient performance, reliable safety protections and a broad operating range

Equipped with a vertical double-duct air sleeve to optimize airflow dynamics

Forced fan cooling intake structure limits the fan’s maximum operating temperature to <50 ℃, enabling long-term, extended service life

Speed-regulating fan supports safe processing of light, small and powdery sample types

Intuitive operation with support for constant-temperature operation, timed cycles and automatic stop functionality

Dedicated function keys allow for straightforward, accurate temperature setting

Advanced insulated door technology maintains low exterior door temperatures and prevents deformation under high-temperature operating conditions

Pull-out tray and partition design enables quick, convenient sample access and retrieval

specifications

Model | Digital Liquid | LGP30D | LGP45D | LGP65D | LGP85D | LGP125D | LGP230D |

|---|---|---|---|---|---|---|---|

Crystal type | LGP30L | LGP45L | LGP65L | LGP85L | LGP125L | LGP230L | |

Touch screentype | LGP30T | LGP45T | LGP65T | LGP85T | LGP125T | LGP230T | |

Internalcirculation method | incubator:RT+10-80℃;Dry oven:RT+80-250℃ | ||||||

Performance | Temperaturecontrol range | 0.1℃ | |||||

Temperatureresolution | incubator:±0.5℃;Dry oven:±1℃ | ||||||

Constant temperaturefluctuation | incubator:±1%;Dry oven:±2.5% | ||||||

Constitute | InteriorMaterial | stainless steel | |||||

ExteriorMaterial | Cold rolledsteel sheet, surface coating | ||||||

Thermalinsulation material | Aluminumsilicate fiber | ||||||

Heater | Stainless steel heatingpipe | Nickel-chromiumalloy heating wire | |||||

Rated power Dryoven | 0.8kw | 1.2kw | 1.6kw | 1.8kw | 2.3kw | 3.0kw | |

Rated powerincubator | 0.3kw | 0.3kw | 0.4kw | 0.6kw | 0.6kw | 0.7kw | |

Exhaust vent | Inner diameter28mm*1, located at the top | ||||||

Controller | Temperaturecontrol mode | D: Digital tubedual-row PID; L: LCD dual-row PID; T: 5-inch color touch screen fuzzy PID | |||||

Temperaturesetting mode | D/L: Touchfour-button setting and touch screen input setting; T: touch screen setting | ||||||

Temperature representation | T:Measurementtemperature display:Upper display on touch screen, set temperaturedisplay:lower display on touch screen | ||||||

D: Measurementtemperature display: 4-digit upper display; set temperature display: 4-digitlower display | |||||||

L: Measurementtemperature display: LCD upper display; set temperature display: LCD lowerdisplay | |||||||

Timer | 0~9999min (withtiming waiting function) | ||||||

Operationfunction | fixed valueoperation, timing operation, automatic stop | ||||||

Program mode | D/L is optional,T single-stage temperature control and program temperature control can beinterchanged, 50 experimental programs can be stored, each program can be setwith 50 steps, and each step can be set for 0-6000 minutes, adjustable | ||||||

Additional functions | Deviationcorrection, menu key locking, power failure compensation, power failurememory( L,T: | ||||||

Safety device | Sensor | Pt100 | |||||

Specifications | Over rise alarm,type D optional,L、T standard | ||||||

Internaldimensions (mm) | 310*310*310 | 350*350*350 | 400*360*450 | 450*450*450 | 500*450*550 | 600*500*750 | |

ExternalDimensions (mm) | 428*505*710 | 468*538*753 | 518*550*860 | 567*640*853 | 617*639*953 | 735*625*1220 | |

Package size | 552*578*840 | 592*618*880 | 642*628*980 | 692*718*980 | 742*718*1080 | 898*814*1347 | |

Internal volume | 30L | 45L | 65L | 85L | 125L | 230L | |

Diaphragmbearing | 15kg | ||||||

Number ofshelves | 5 | 6 | 8 | 8 | 11 | 17 | |

Shelf spacing | 40mm | ||||||

Rated current | AC220V/3.6A | AC220V/5.5A | AC220V/7.2A | AC220V/8.2A | AC220V/10.5A | AC220V/13.6A | |

Configurationcan be increased | Shelf, RS485interface, printer, recorder, external communication, remote control, Programtemperature controller, wireless SMS alarm, U disk data storage | ||||||

why choose us

Premium Quality with CE & ISO

We conduct 100% performance testing on every unit, ensuring its stable operation and superior performance in your application.

24/7 Expert Technical Support

Our senior engineers are on standby 24/7, ready to provide expert solutions at any time to minimize your operational downtime.

20+ Years R&D & Production

Our deep technical expertise is your solid guarantee for professional and reliable OEM/ODM services.

Trusted in 80+ Countries

Industry leaders and research institutions in over 80 countries and regions rely on our equipment for stable operation.

True Manufacturer, Factory-Direct Price

Bypass the middlemen to get our factory pricing and speak directly with our core engineers.

Rapid & Reliable Delivery

Our extensive in-stock inventory provides a solid guarantee for rapid and reliable global delivery.

Our Factory

20 Years

58 Experts

20000 m²

7X24 Hours