Jacketed Stainless Steel Chemical Reactor: Ideal for Pharmaceutical & Chemical Processing, -120~260℃ Range

Crafted from SUS304 or SUS316L stainless steel, the jacketed stainless steel chemical reactor offers superior corrosion, high-temperature, and pressure resistance, with a durable, damage-resistant surface that’s easy to clean. It serves industrial chemical production, pharmaceuticals, food processing, petrochemicals, and high-temperature high-pressure reactions.

- modelLSR-10L

- brandLABEKS

- min. order1 pcs

- packageplywood case package

description

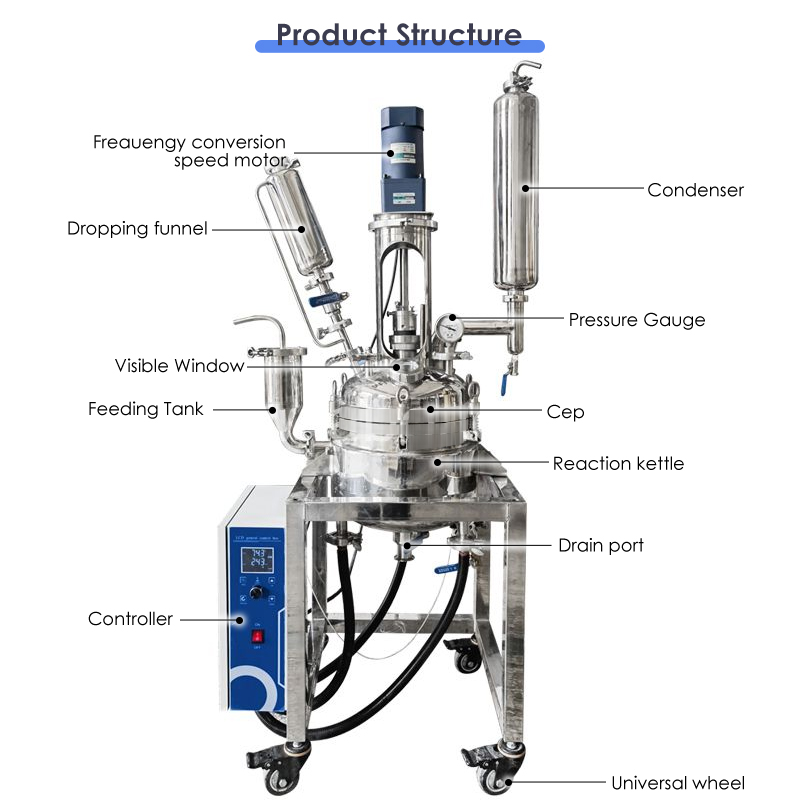

Engineered with a double-layer stainless steel construction, the jacketed stainless steel chemical reactor houses reaction solvents in its inner chamber for stirred reactions, while its interlayer connects to various cold and heat sources—including refrigeration fluids, hot water, or hot oil—to enable cyclic heating or cooling. Under set constant temperature conditions, stirred reactions can be conducted at atmospheric or negative pressure within the sealed vessel, with support for reflux and distillation processes. This unit is the ideal pilot and production equipment for modern fine chemical plants, biopharmaceutical facilities, and new material synthesis operations.

features

The entire reactor system is constructed from SUS316L or SUS304 stainless steel, delivering excellent chemical and mechanical stability.

Equipped with a variable frequency AC induction motor for speed regulation, this unit maintains constant rotational speed without brushes or sparks, ensuring safe, stable, and continuous operation.

Its jacketed interface supports connection to hot oil for cyclic heating reactions, or to refrigeration fluids for low-temperature reaction processes.

The eight-port reactor lid (configurable) includes oversized openings for straightforward cleaning, with standard port sockets that allow optional assembly of reflux and distillation synthesis setups.

Featuring a removable stainless steel ball valve at the bottom discharge port, the reactor eliminates container dead spaces, simplifying the discharge of solid materials.

Room-temperature reactions are supported, with tap water circulation enabling rapid removal of generated reaction heat.

specifications

Model | LSR-10L |

|---|---|

Kettlevolume | 10L |

Mezzaninevolume | 3.8L |

Voltage/frequency | 220V/50Hz |

Reactiontemperature | -120~260℃ |

Pressure | -0.1~0.3Mpa |

Stirringspeed | 0-460rpm |

Power | 200W |

Sealedform | Stainlesssteel graphite combination mechanical seal |

Numberof cauldron lid openings | Eightports (optional) |

Material | SUS316L/SUS304 |

Sightglass | Φ32 |

Scrapersight glass | Φ51 |

Temperaturemeasuring hole | 50.5chuck/Φ8 temperaturemeasuring tube |

Returnhole | 50.5chuck/1000ml funnel |

Drophole | 50.5chuck/Φ38 return port |

Pressuregauge | 50.5chuck/± integrated pressure gauge |

Impeller | 2-pointexhaust valve |

Exhaust | SUS316Lpropeller mixing paddle |

Bottomvalve | 50.5chuck/Φ89 columncooling |

Overalldimensions | 480*480*1560mm |

Optional(Additionalfee) | Explosion-proofwhole machine/ electricheating/full316L/collection tank/ mobileframe /spraying PTFE |

why choose us

Premium Quality with CE & ISO

We conduct 100% performance testing on every unit, ensuring its stable operation and superior performance in your application.

24/7 Expert Technical Support

Our senior engineers are on standby 24/7, ready to provide expert solutions at any time to minimize your operational downtime.

20+ Years R&D & Production

Our deep technical expertise is your solid guarantee for professional and reliable OEM/ODM services.

Trusted in 80+ Countries

Industry leaders and research institutions in over 80 countries and regions rely on our equipment for stable operation.

True Manufacturer, Factory-Direct Price

Bypass the middlemen to get our factory pricing and speak directly with our core engineers.

Rapid & Reliable Delivery

Our extensive in-stock inventory provides a solid guarantee for rapid and reliable global delivery.

Our Factory

20 Years

58 Experts

20000 m²

7X24 Hours