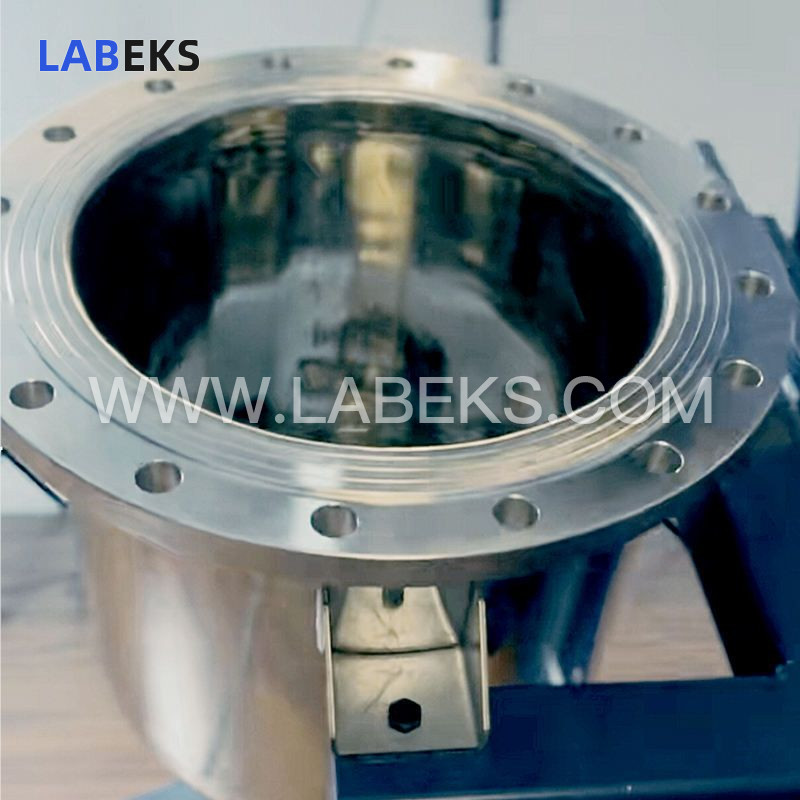

Electric Lifting Stainless Steel Reactor – 360° Rotatable for Simplified Cleaning & Material Handling

Engineered for efficient processing of viscous materials, this stainless steel reactor boasts electric lifting for raising/lowering the entire lid and stirring system, plus 360° kettle rotation to enable direct material discharge and simplified internal cleaning.

- modelLSR-S Series

- brandLABEKS

- min. order1 pcs

- packageplywood case package

description

Building on the design of standard reactors, this lifting and rotating unit enables the entire reactor cover and its upper components to be raised as one. Once the stirring rod is clear of the kettle body, the unit can be rotated 360 degrees to the left via handwheel for direct material discharge, streamlining reactor cleaning processes.

features

7. The complete kettle body and lid assembly can be electrically lifted or lowered, while the kettle body itself can be manually rotated 360 degrees for enhanced operational flexibility.

2. Constructed entirely from SUS316L or SUS304 stainless steel, the reactor offers excellent chemical and physical stability, with resistance to acids, alkalis and high temperatures.

1. Equipped with a brushless AC induction motor featuring frequency conversion speed control, this unit delivers constant, spark-free, stable operation for continuous use, with optional explosion-proof motor customization available.

3. Its jacketed interface supports connection to hot oil circulation systems for heating reactions, or to coolant fluids for low-temperature reaction processes.

4. Suitable for room-temperature reactions, the reactor can rapidly dissipate reaction-generated heat via tap water circulation through its jacket.

6. The reactor cover comes with eight standard ports (customizable), including an oversized port for simplified cleaning, with standard sockets enabling optional integration of reflux and distillation synthesis equipment.

5. A stainless steel ball valve at the bottom discharge port eliminates container dead space; it is also removable to simplify discharge of solid materials.

specifications

Model | LSR-S Series |

|---|---|

Kettlevolume | 10L/20L/30L/50L/100L/200L |

Mezzaninevolume | 3L/5L/10L/20L/30L |

Voltage/frequency | 220V/50Hz |

Reactiontemperature | -120~260℃ |

Pressure | -0.1~0.3Mpa |

Stirringspeed | 0-460rpm |

Power | 200W |

Sealedform | Stainlesssteel graphite combination mechanical seal |

Numberof cauldron lid openings | Eightports (optional) |

Material | SUS316L/SUS304 |

Impeller | SUS316Lpropeller mixing paddle |

Exhaust | 2-pointexhaust valve |

Bottomvalve | Φ35/50.5chuck |

Optional(Additionalfee) | Explosion-proofwhole machine/ electricheating/Total 316L/collection tank/ mobileframe /spraying PTFE |

why choose us

Premium Quality with CE & ISO

We conduct 100% performance testing on every unit, ensuring its stable operation and superior performance in your application.

24/7 Expert Technical Support

Our senior engineers are on standby 24/7, ready to provide expert solutions at any time to minimize your operational downtime.

20+ Years R&D & Production

Our deep technical expertise is your solid guarantee for professional and reliable OEM/ODM services.

Trusted in 80+ Countries

Industry leaders and research institutions in over 80 countries and regions rely on our equipment for stable operation.

True Manufacturer, Factory-Direct Price

Bypass the middlemen to get our factory pricing and speak directly with our core engineers.

Rapid & Reliable Delivery

Our extensive in-stock inventory provides a solid guarantee for rapid and reliable global delivery.

Our Factory

20 Years

58 Experts

20000 m²

7X24 Hours