CM30 Series Coating Thickness Gauge with High Accuracy for Automotive & Aerospace Quality Control

Designed for precise, non-destructive measurement of surface coatings such as paint and electroplated layers, the coating thickness gauge enables reliable quality inspection and process control across automotive manufacturing, metal processing, aerospace, construction, and industrial corrosion prevention sectors.

- modelCM30 Series

- brandLABEKS

- min. order1 pcs

- packageplywood case package

description

As a specialized non-destructive testing instrument, the CM30 Series coating thickness gauge delivers precise measurements of surface coatings—including paints, electroplated layers, and anti-corrosion coatings—on various substrates. Leveraging techniques such as magnetic induction, eddy current, ultrasound, or optics, it rapidly identifies thickness discrepancies between coatings and base materials, ensuring strict adherence to industrial standards and process specifications. This device is widely utilized in automotive manufacturing, shipbuilding, aerospace, electronics, steel structure engineering, and industrial corrosion protection applications.

features

1. High Accuracy and High Resolution: Boasting micron-level or superior measurement accuracy and resolution, this gauge delivers consistent, dependable results to meet the stringent quality control requirements of industrial applications.

2. Intelligent Calibration and Automatic Recognition: Supports automatic zero-point calibration and multi-point calibration. Premium models can automatically detect substrate types and switch measurement modes, streamlining operations and minimizing human-induced errors.

3. Multifunctional Measurement Capabilities: Compatible with a wide range of coating types (including paint, electroplating, galvanizing, anodizing, etc.) and supports various substrates (such as iron/steel and other magnetic metals, aluminum, copper, stainless steel, and other non-magnetic metals).

4. Data Storage and Statistical Functions: Equipped with large-capacity internal memory capable of storing thousands of measurement datasets, along with built-in basic statistical analysis tools (mean value, maximum value, minimum value, standard deviation, etc.) to facilitate comprehensive quality traceability.

5. User-Friendly and Easy Operation: Features intuitive menu navigation and a simple button or touchscreen interface for effortless use. Its ergonomically designed probe ensures a stable grip and consistent measurements.

6. Diverse Display and Connectivity: Comes with a backlit LCD screen for clear, easy-to-read measurements. Supports data export via USB and Bluetooth, enabling seamless connection to computers or printers for report generation and in-depth analysis.

7. Portable Design and Durability: Typically features a compact, lightweight build ideal for on-site testing. Its rugged casing and wear-resistant probe ensure long-lasting performance even in harsh industrial environments.

8. Dedicated Probes and Accessory Options: Offers a selection of probe variants (integrated, separate, miniature, high-temperature, etc.) to accommodate different workpiece shapes (flat surfaces, curved surfaces, small pipes) and special operating conditions (high-temperature workpieces).

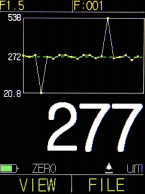

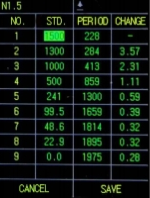

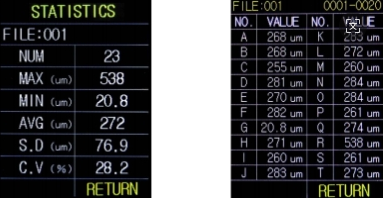

Large Value Interface | Statistics Interface | Tendency Chart Interface |

|---|---|---|

2.4-inch 320×240 dot-matrix color IPS screen with crisp, bright visuals. Its eye-catching large-value interface features bold font display and a streamlined layout, ensuring intuitive reading. | The Statistics Interface presents measured values alongside 6 key statistical metrics: number of tests, average value, maximum value, minimum value, standard deviation, and coefficient of variation, allowing real-time observation of measurement data trends. | The trend chart displays the latest 20 measurement results, showing both individual testing values and the real-time average value for quick performance tracking. |

|

|

|

User Calibration Function | File Management | |

The user calibration function supports probe calibration from several to dozens of points as required, compatible with 4 probe types utilizing distinct testing principles. This ensures highly accurate and stable measurement readings. | It can store up to 200,000 testing values across 200 numbered files, with each file holding 1,000 values and corresponding statistical data. Users can switch between file numbers as needed. In the Read Storage interface, the first page displays statistical data, while subsequent pages show 20 individual measurement values per page. | |

|

| |

specifications

Model | CM30F | CM30N | CM30FH | CM30FN | |||||

|---|---|---|---|---|---|---|---|---|---|

Probe Model | F3 | N2 | F10 | FN1.5 | |||||

Working Principle | Magnetic | Eddy Current | Magnetic | Magnetic/ Eddy Current | |||||

Measurement Range ( μm) | 0~3000 | 0~2000 | 0~10000 | 0~1500 | |||||

Resolution ( μm) | 0.1 | 0.1 | 0.1 | 0.1 | |||||

Indication Error ( μm) | ±(2%H+2) | ±(2%H+2) | ±(2%H+10) | ±(2%H+2) | |||||

Testing Conditions (mm) | Min. Radius of Curvature (Convex) | 5 | 5 | 10 | 5 | ||||

Min. Area Diameter | Φ20 | Φ20 | Φ40 | Φ20 | |||||

Base Material Critical Thickness | 0.5 | 0.5 | 2 | 0.5 | |||||

Technical Specifications | |||||||||

Display | 2.4 ”(320 ×240)IPS Color LCD Screen | ||||||||

Working Principle | Magnetic/Eddy Current(Non-Magnetic) | ||||||||

Unit | Metric(Micrometer, Millimeter) / Imperial (Mils) | ||||||||

Resolution | High/Low (only in the Metric mode) | ||||||||

Language | Chinese / English | ||||||||

Storage Capacity | 200 files, each file can store 1000 measurement values and 6 statistics | ||||||||

Power Off | Automatically shut down after 3 minutes without operation or shut downmanually | ||||||||

Communication Interface | USB 2.0 Full Speed Interface | ||||||||

Power | Two 1.5V AA Batteries | ||||||||

Operation Time | 20 Hours | ||||||||

Operating Environment | -10 to +50℃Non-strongmagnetic field environment | ||||||||

Dimension | 121.5mm*63.5mm*31.5mm | ||||||||

Weight | 317g(Exclude probe and batteries) | ||||||||

Standard Configuration | |||||||||

CM30 Gauge | 1 | AA Battery | 2 | Zero Plate | 1(F,N,FH) 2 (FN) | ||||

USB Communi cation Cable | 1 | DataView Software (CD) | 1 | Probe | 1 | ||||

Operation Manual | 1 | Instrument Seal Box | 1 | Calibration Foil | 5 | ||||

Optional Configurations | |||||||||

Probe(Including Calibration Foils) | F3 | N2 | FN1.5 | F10 | |||||

Zero Plate | Fe Zero Plate,Al Zero Plate | ||||||||

Calibration Foil | Various thickness foils are available | ||||||||

why choose us

Premium Quality with CE & ISO

We conduct 100% performance testing on every unit, ensuring its stable operation and superior performance in your application.

24/7 Expert Technical Support

Our senior engineers are on standby 24/7, ready to provide expert solutions at any time to minimize your operational downtime.

20+ Years R&D & Production

Our deep technical expertise is your solid guarantee for professional and reliable OEM/ODM services.

Trusted in 80+ Countries

Industry leaders and research institutions in over 80 countries and regions rely on our equipment for stable operation.

True Manufacturer, Factory-Direct Price

Bypass the middlemen to get our factory pricing and speak directly with our core engineers.

Rapid & Reliable Delivery

Our extensive in-stock inventory provides a solid guarantee for rapid and reliable global delivery.

Our Factory

20 Years

58 Experts

20000 m²

7X24 Hours