50L Rotary Evaporator with High Solvent Recovery for Chemical Laboratories

Engineered for efficient and gentle solvent removal from samples via evaporation, the rotary evaporator—also referred to as a rotavap or rotovap—acts as an essential device in chemical laboratory environments.

- modelLRE-50

- brandLABEKS

- min. order1 pcs

- packageplywood case package

description

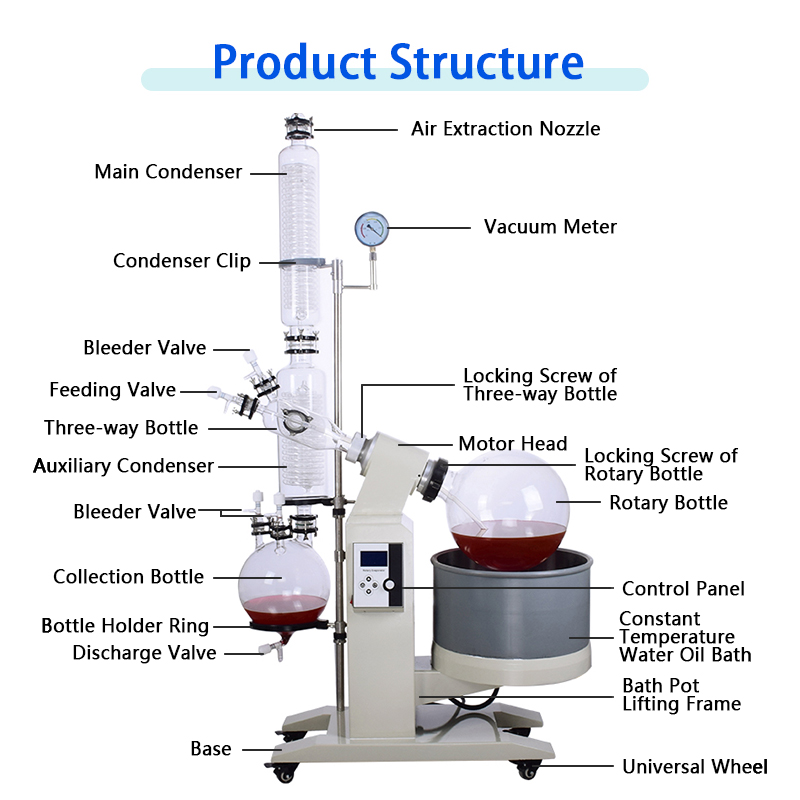

Featuring a stepless speed-controlled glass rotary flask that rotates at a constant speed, this system distributes materials into a large, uniform thin film along the flask’s inner wall. Under vacuum conditions, an intelligent constant-temperature water bath provides uniform heating for high-speed evaporation; vapor is then cooled by an efficient glass condenser and collected in the receiving flask.

features

1. The main frame is constructed from stainless steel + aluminum alloy, with a rational structural design that optimizes material stress distribution for enhanced durability.

2. All glass components are made of high borosilicate glass (GG-17), offering exceptional high-temperature resistance and corrosion protection.

3. The sealing system adopts a dual combination of imported fluororubber and Teflon, ensuring long-lasting corrosion resistance and stable high vacuum performance.

4. Equipped with a vertical three-tier serpentine coil condenser, the primary + secondary dual-condenser configuration guarantees an extremely high solvent recovery rate.

5. A DC brushless motor provides stable rotation, spark-free operation, and smooth torque ramp-up.

6. An LCD full-screen display enables dual digital readouts of temperature and rotation speed; bath temperature is controlled by a precision PT100 sensor for fast, accurate temperature transmission.

7. All valves feature the latest single-handle wheel design, delivering superior sealing while simplifying and streamlining operation.

8. Operation is managed via a microcomputer-controlled power switch for reliable system control.

9. The water bath supports electric lifting, with a deceleration power motor used for the lifting mechanism to ensure smooth, stable movement.

10. The bath liner is crafted from premium 304 stainless steel for corrosion resistance and long service life; an outer silicone layer enhances safety during high-temperature operation.

11. A vacuum pressure gauge provides real-time vacuum level readings; the oil-filled gauge offers anti-vibration properties for stable measurements.

12. Continuous feeding is supported via a valve-type feed valve paired with a PTFE tube for convenient sample addition during operation.

13. The receiving flask is equipped with a discharge valve, facilitating easy collection and draining of evaporated extracts.

14. Check valve control enables continuous discharge; the system allows vacuum switching even while in operation.

15. Over-temperature safety protection is included: if the actual temperature exceeds the set temperature by 5°C, the machine will automatically shut off power.

16. An anti-dry heating function triggers automatic power-off when the water level in the heating bath drops below the heating tube.

17. In the event of a sudden power outage followed by restoration, the machine will automatically stop heating to prevent safety hazards.

specifications

Model | LRE-50 |

|---|---|

Voltage/Frequency | 220V/50HZ |

Whole power | 6640W |

Rotary power | 100W 1/5 |

Lifting power | 40W 1/12.5 |

Heating power | 6500W |

Vacuum degree | 0.0095Mpa |

Rotary flask volume | 50L,Φ470mm/Φ125 flange port |

Receiving flask volume | 20L,Φ355mm/ upper with Φ60 flange port*Φ35 flangeport*Φ2*down with Φ50 flange port |

Rotary speed | 0-120rpm/min |

Temp.cotrolling range | room temperature -180℃ |

Temp. accuracy | ±1℃ |

Flask lifting distance | 215mm |

Condenser size | The main condensor Φ160*835H(mm) ,upper with Φ60 flange*downwith Φ80 flangeThe assisted condensor Φ160*530H(mm) ,upper with Φ80 flange *down with Φ60flange *side with Φ60 flange |

Condensation area | 1.44(0.95+0.49)㎡ |

Air guide bottle | Left with Φ35 flange,upper with Φ35flange,side with Φ60 flange,rightΦ60 flange |

Charging valve | Φ35 flange,glass+PTFE valve,feed nozzle (pagoda-shape connectors) outer diameter 12mm |

Multi-function port | Φ35 flange,glass+PTFE valve, glass nozzle (pagoda-shape connectors)outer diameter 12mm |

Vacuum suction nozzle | Φ60 flange glass exhaustor, suction nozzle (pagoda-shapeconnectors), outer diameter 10mm |

Condensing coil in and out circuation nozzle | Pagoda-shape connectors, outer diameter 16mm |

Vent valve | Φ35 flangeport*2,glass+PTFE valve, vent nozzle (pagoda-shape connectors), outer diameter 12mm |

Baiting valve | Φ50 flange port, side discharging nozzle(pagoda-shapeconnectors), outer diameter 20mm, 300mm from the floor |

Pot bravery size | Φ550*320H(mm)about 76L |

Overall dimensions (W*L*H) | 1390*700*2300mm |

Net weight | 97kg |

Packing dimensions | 1230*630*1420 ,1.1m³ |

Packing weight | 142kg |

why choose us

Premium Quality with CE & ISO

We conduct 100% performance testing on every unit, ensuring its stable operation and superior performance in your application.

24/7 Expert Technical Support

Our senior engineers are on standby 24/7, ready to provide expert solutions at any time to minimize your operational downtime.

20+ Years R&D & Production

Our deep technical expertise is your solid guarantee for professional and reliable OEM/ODM services.

Trusted in 80+ Countries

Industry leaders and research institutions in over 80 countries and regions rely on our equipment for stable operation.

True Manufacturer, Factory-Direct Price

Bypass the middlemen to get our factory pricing and speak directly with our core engineers.

Rapid & Reliable Delivery

Our extensive in-stock inventory provides a solid guarantee for rapid and reliable global delivery.

Our Factory

20 Years

58 Experts

20000 m²

7X24 Hours