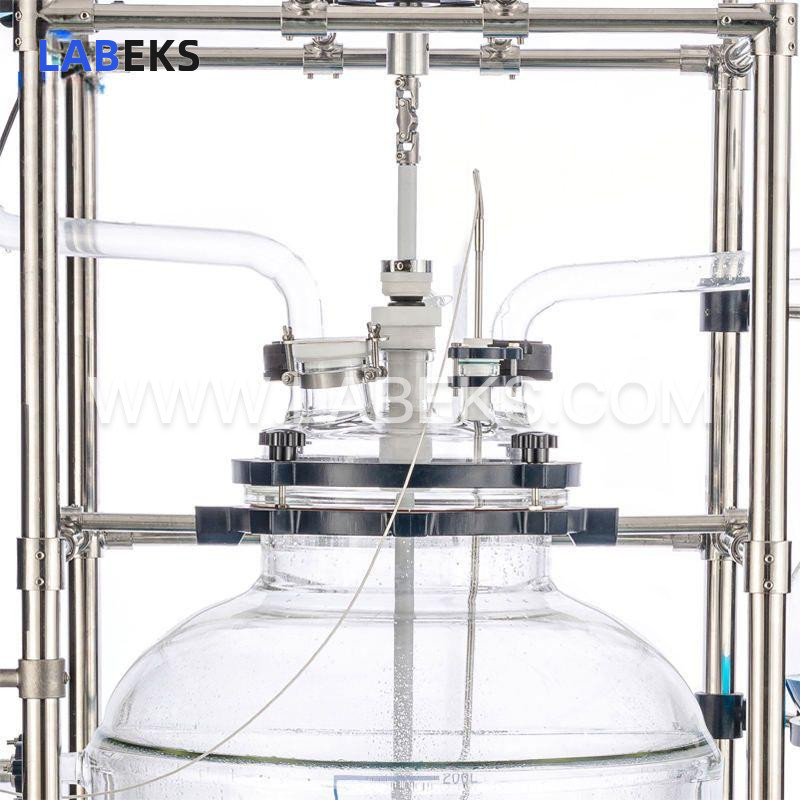

200L Jacketed Glass Reactor for Vacuum & Temperature-Controlled Reactions

Engineered for vacuum and temperature-regulated synthetic reactions, the 200L jacketed glass reactor features high borosilicate glass vessels with bottom valves, multi-port domes, PTFE-coated stirrers, adjustable-speed drives, and CE/ISO certifications.

- modelLGR-200L

- brandLABEKS

- min. order1 pcs

- packageplywood case package

description

Jacketed glass reactors facilitate synthetic reactions of various materials within precisely controlled temperature and vacuum environments. Serving as an all-in-one solution, they support extraction, purification, distillation, and homogenization processes.

Featuring an inner vessel with one or two jackets, these reactors leverage temperature differentials generated by chillers to regulate internal conditions. Designed to operate under vacuum, they are perfect for air-sensitive applications. Constructed from glass, they are available in capacities ranging from 1L to 200L.

features

Complete glassware system constructed from GG3.3 borosilicate glass, offering excellent resistance to heat, cold, and corrosion.

Broad operating temperature range spanning -60°C to 250°C.

Solvent-resistant PTFE seals deliver long-lasting durability and reliable performance, maintaining a vacuum level of -0.098Mpa.

Robust stainless steel-reinforced PTFE stirrer with anchored agitator, suitable for processing a broad range of viscous materials; multi-layer stirring blades are available as an optional upgrade.

Integrated PT100 temperature sensor with LCD display provides precise, user-friendly temperature monitoring.

Variable-frequency AC induction motor ensures constant, brushless, spark-free operation for stable, continuous performance.

Heavy-duty stainless steel support frame with lockable casters balances mobility and stability; the entire frame and glass vessel are shipped pre-assembled for quick setup.

Bottom flange discharge port featuring a PTFE valve, secured with aluminum flange components.

specifications

Model | LGR-200L | |

|---|---|---|

Kettle volume | 200L,inner diameter 600mm, outer diameter 650mm,innerlength 840mm | |

Jacketed volume | about 40L | |

Voltage/frequency | 220V/50HZ | |

Stirring power | 750W1/5 | |

Stirring speed | 0-280r/min | |

Temperaturerange vessel can bear | -80℃to 250℃ | |

Temperatureaccuracy | ±1℃ | |

Vacuum degree | 0.098MpaNegative pressure | |

Cover diameter | Φ340mm | |

6ports of cover | Stirring port | Φ60mm flangeport |

Condenser refluxport | 50# ball millport | |

Adding dropwiseelbow port | 50# ball millport | |

Relief port | 34# standardport | |

Temperaturemeasure port | Φ45mm flangeport | |

Solid feedingport | Φ80mm flangeport,inner diameter Φ60mm matched with PTFEcover | |

Stirringpaddle | Φ20*1300H(mm),leafing 240mm | |

Condenser size | Φ160*600H(mm),down with Φ60mm flange port | |

Condensationarea | 0.95㎡ | |

Reflux elbow | upper with Φ60mmflange port,left with 50# ball mill plug,right with 24# standard port matched with functionalvalve, down with 50# ball mill plug valve | |

Adding dropwisebottle | 5L,tubular,upper with 29# standard port matched with vent valve *2, 34# standard portmatched with glass plug | |

Receiving bottle | 10L,upper with 50# ball mill port,24# standard port matched with vent valve*2, down with glassbaiting valve | |

Relief valve | 34# standardplugvalve,vent nozzle (pogada connector), outer diameter 12mm | |

In and outcirculation port of the sandwich | Φ45mm flangeport matched with ring flange, 6 points outside the wire adapter | |

Baiting port | Φ100mm flange,Φ65mm baiting port,inclineddischarged port (pagoda connector), Φ40mm,from floor 300mm | |

Vacuum suctionnozzle | padogaconnector,outer diameter 12mm | |

In and outcirculation nozzle of condenser coil | padogaconnector,outer diameter 15mm | |

Overalldimension (W*L*H) | 1250*930*2800mm | |

Net weight | 175kg | |

Packingdimension | 2200*790*875mm,1385*880*910mm, 2.63m³ | |

Packing weight | 271kg (159+112) | |

why choose us

Premium Quality with CE & ISO

We conduct 100% performance testing on every unit, ensuring its stable operation and superior performance in your application.

24/7 Expert Technical Support

Our senior engineers are on standby 24/7, ready to provide expert solutions at any time to minimize your operational downtime.

20+ Years R&D & Production

Our deep technical expertise is your solid guarantee for professional and reliable OEM/ODM services.

Trusted in 80+ Countries

Industry leaders and research institutions in over 80 countries and regions rely on our equipment for stable operation.

True Manufacturer, Factory-Direct Price

Bypass the middlemen to get our factory pricing and speak directly with our core engineers.

Rapid & Reliable Delivery

Our extensive in-stock inventory provides a solid guarantee for rapid and reliable global delivery.

Our Factory

20 Years

58 Experts

20000 m²

7X24 Hours