100L Single Layer Glass Reactor with 0.098Mpa Vacuum for Chemical Synthesis

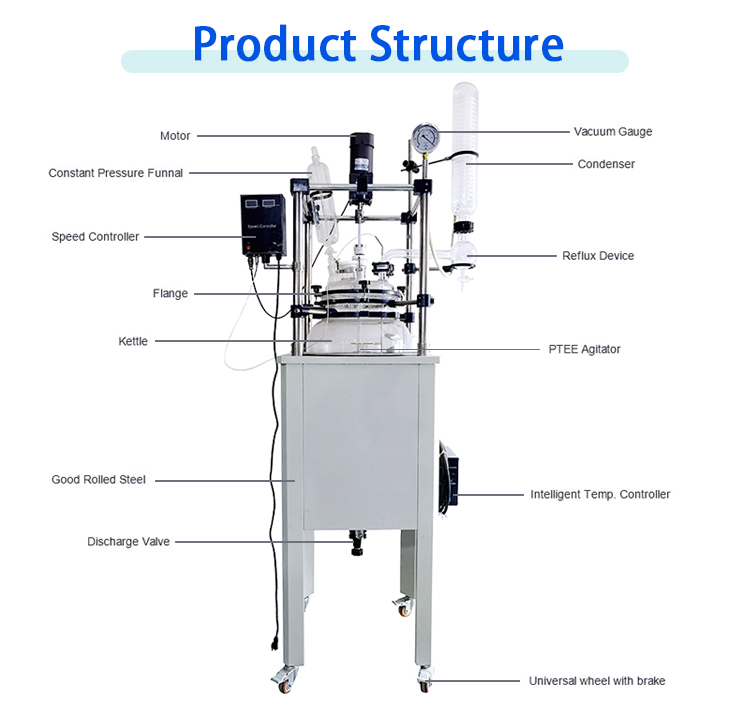

For precise constant-temperature biochemical and synthesis reactions, this glass reactor integrates vacuum operation, distillation, reflux, stirring, oil/water heating, and heating mantle functions in a fully enclosed system, ideal for lab preparation and production use.

- modelLGR-100F

- brandLABEKS

- min. order1 pcs

- packageplywood case package

description

The inner vessel of this single layer glass reactor holds reaction solvents for stirring operations, and is heated via computer-controlled oil bath or electric heating. Operable under either atmospheric or vacuum conditions, it enables precise control of reaction solution reflux and distillation. As an ideal apparatus for modern synthetic chemistry, biopharmaceuticals, and new material development, it supports both laboratory preparation experiments and small-scale production.

features

1. Featuring PTFE (Ceramic) mechanical seals and proprietary technology, this reactor delivers the highest vacuum performance available among comparable market products;

2. All glass components are crafted from GG3.3 high borosilicate glass, offering excellent chemical and physical stability; its large-vessel design allows for easy manual cleaning;

3. Integrated frequency control with an AC induction motor ensures constant, digitally displayed stirring speeds. Brushless and spark-free, it operates safely and stably for continuous run times;

4. The computer-controlled thermostatic oil bath utilizes intelligent PID regulation for accurate, user-friendly temperature control;

5. A dead-corner-free PTFE bottom valve enables smooth discharge of both solid and liquid materials from the reactor base;

6. Constructed with a full stainless steel frame—including stainless steel foot connectors such as tees and four-way valves—it is compact, robust, and remains stable without shaking during stirring operations;

7. Brake-equipped casters enable convenient and secure mobility of the unit;

8. Its scientifically designed integral structure boasts a streamlined, aesthetic appearance and facilitates straightforward operation;

9. Explosion-proof configurations are available upon request;

(Upon customer request, we can integrate cooling coils and explosion-proof components into the system)

specifications

Model | LGR-100F | |

|---|---|---|

Kettle volume | 100Ltubular,Φ465mm, internallength 696mm | |

Voltage/frequency | Stirring220V/50HZ, heating pot 380V/50HZ | |

Stirring power | 200W,1/3 | |

Heating power | 8KW | |

Stirring speed | 0-450rpm/min | |

Bath temperaturerange | room temperatureto 180℃ | |

Temperatureaccuracy | ±1℃ | |

Vacuum degree | 0.098Mpa | |

Kettle size | Cover Φ340mm | |

6 ports on cap | Stirring port | Φ60mm flangeport |

Condenser refluxport | 50# ball millport | |

Constantpressure funnel port | 40# standardport | |

Relief port | 34# standardport | |

Temperaturemeasuring port | Φ45 flange port | |

Solid feedingport | Φ80mm flangeport, inner diameter Φ60mm matched with PTFE cover | |

Stirringpaddle | Φ17*1200H(mm),leafing 240mm | |

Condenser size | Φ120*600H(mm),down with Φ60 flange port | |

Condenser area | 0.5㎡ | |

Reflux elbow | upper with Φ60flange port,left with 50# ball mill plug ,down with1L spherical bottle matched with glass baiting valve | |

Constantpressure funnel | 2L,upper with 29# standard port match with glass plug,down with 40# standard plug | |

Relief valve | 34# standardplug valve, vent nozzle (pagoda connector), outer diameter 12mm | |

Baiting valve | Φ80 flange port,Φ33mm baiting port,inclineddischarging port (pagoda connector)Φ34mm,from the floor 350mm | |

Vacuum suctionnozzle | padogaconnector,outer diameter 12mm | |

In and outcirculation nozzle of condenser coil | padogaconnector,outer diameter 15mm | |

Pot braverydimension | Φ550*650H(mm) | |

Overalldimension (W*L*H) | 900*770*2550mm | |

Net weight | 110kg | |

Packingdimension | 2050*690*1000mm,1.42m³ | |

Packing weight | 163kg | |

why choose us

Premium Quality with CE & ISO

We conduct 100% performance testing on every unit, ensuring its stable operation and superior performance in your application.

24/7 Expert Technical Support

Our senior engineers are on standby 24/7, ready to provide expert solutions at any time to minimize your operational downtime.

20+ Years R&D & Production

Our deep technical expertise is your solid guarantee for professional and reliable OEM/ODM services.

Trusted in 80+ Countries

Industry leaders and research institutions in over 80 countries and regions rely on our equipment for stable operation.

True Manufacturer, Factory-Direct Price

Bypass the middlemen to get our factory pricing and speak directly with our core engineers.

Rapid & Reliable Delivery

Our extensive in-stock inventory provides a solid guarantee for rapid and reliable global delivery.

Our Factory

20 Years

58 Experts

20000 m²

7X24 Hours