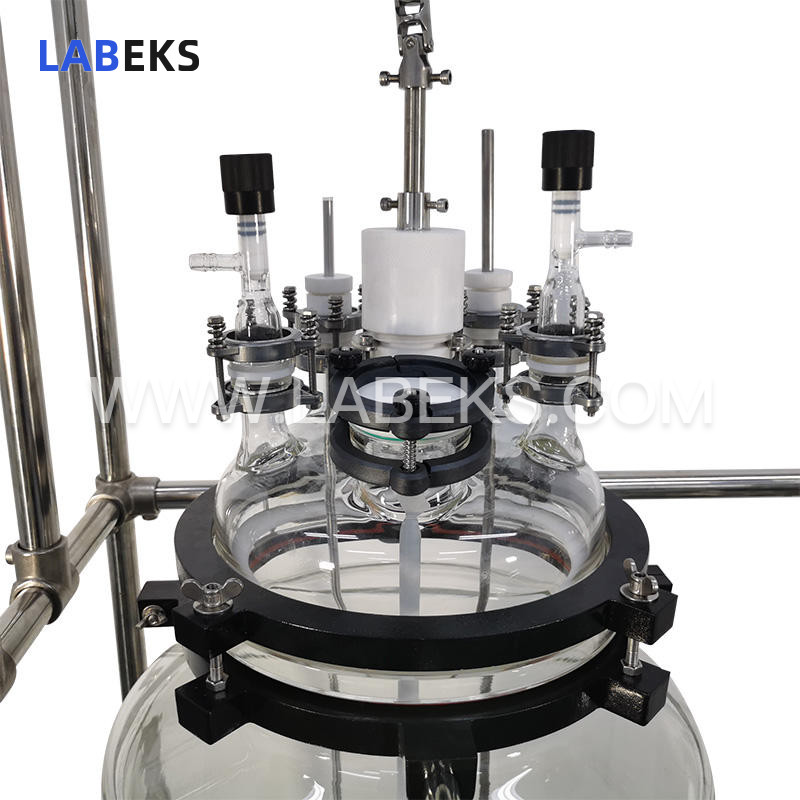

100L Crystallization Filter Jacketed Glass Reactor: Integrated Filtration for Biopharmaceutical Pilot Production

Ideal for vacuum filtration, concentration, distillation, extraction and crystallization, this crystallization filter jacketed glass reactor supports biopharmaceutical operations, peptide synthesis, scientific research, as well as small-scale and pilot-scale production runs.

- modelLCR-100L

- brandLABEKS

- min. order1 pcs

- packageplywood case package

description

As a widely utilized biochemical instrument, the crystallization filter jacketed glass reactor integrates reactor and filtration functionalities into a single unit. It is engineered for chemical reactions and physical processes involving synthesis, catalysis, or other solid-liquid operations in laboratory and manufacturing settings, enabling execution of one or more procedures within the same vessel (e.g., post-reaction filtration). This eliminates material measurement discrepancies and minimizes reaction substrate transfers, and it serves sectors including pharmaceuticals, peptide synthesis and tobacco research.

All wetted components are chemically inert, enabling compatibility with a broad spectrum of chemicals and solvents. A specialized filter is employed to separate slurry solid particles, forming a filter cake. Filtrate drains to the vessel bottom and can be collected via the bottom outlet valve, while the filter cake can be effortlessly removed to clean the PTFE filter.

This system finds extensive application in pharmaceutical and chemical sectors, particularly for drug synthesis, fine chemical production, petrochemical processing, new material synthesis, concentration, crystallization and related experimental procedures.

features

All glass components are constructed from GG17 borosilicate glass

Imported controller box with intuitive operation, featuring digital display of rotational speed and temperature

PTFE and specialized rubber composite seal that resists diverse solvents while sustaining high vacuum levels

PTFE discharge valve for fast, complete material discharge with zero solvent leakage or contamination

PTFE bottom valve boasting a dead-angle-free design

Optional filter plates with pore sizes ranging from 0.1 to 200μm

Filter plate is easily removable

PTFE or glass mixing paddles available as optional configurations

Stainless steel support frame system for straightforward disassembly

Customization services tailored to specific customer requirements

specifications

Model | LCR-100L |

|---|---|

Material capacity | 100L |

Jacketcapacity | 20L |

Number oflid openings | 6(stir port,temperature measure port, liquid port, solid port, vacuum port, spare port) |

PTFE mixingpaddle | Double layerpush type |

Motor speed | 0-400rpm |

Speed mode | Frequency |

temperaturedisplay | DigitalDisplay |

Dischargevalve | PTFE corethree-way valve can pass hydrogen |

Filterchassis | RemovablePTFE body |

Filter plate | Imported material PTFE core |

Filterdiameter | 277mm |

Sand coreaperture | 40-60μm optional |

Liquid feedvalve | PTFE three-wayvalve |

Sealingmethod | Self-lubricatingmechanical seal |

Useenvironment temperature | 5℃~40℃ |

Size(L*W*H) | 700*700*2100mm |

Voltage | 220V/50Hz (canbe customized) |

Optional | 1. Spraydevice(2 can be used to clean the sign body without dead angle at 360°through negative pressure) 2. Explosion-proofmotors 3. Explosion-proofinverter |

why choose us

Premium Quality with CE & ISO

We conduct 100% performance testing on every unit, ensuring its stable operation and superior performance in your application.

24/7 Expert Technical Support

Our senior engineers are on standby 24/7, ready to provide expert solutions at any time to minimize your operational downtime.

20+ Years R&D & Production

Our deep technical expertise is your solid guarantee for professional and reliable OEM/ODM services.

Trusted in 80+ Countries

Industry leaders and research institutions in over 80 countries and regions rely on our equipment for stable operation.

True Manufacturer, Factory-Direct Price

Bypass the middlemen to get our factory pricing and speak directly with our core engineers.

Rapid & Reliable Delivery

Our extensive in-stock inventory provides a solid guarantee for rapid and reliable global delivery.

Our Factory

20 Years

58 Experts

20000 m²

7X24 Hours