Vacuum Freeze Dryer Lyophilizer with 10.5 ㎡ Drying Area for Pharmaceutical & Biotech Applications

For drying high-end raw materials, Chinese herbal medicine, biological substances, wild vegetables, dehydrated vegetables, food, fruits, chemicals and pharmaceutical intermediates, the LABEKS GZL-10 vacuum freeze dryer lyophilizer enables long-term product preservation, with items recoverable to their original state while retaining full chemical and biological characteristics upon rehydration.

- modelGZL-10

- brandLABEKS

- min. order1 pcs

- packageplywood case package

description

Widely applied in medicine, pharmacy, biological research, chemical engineering and food production, vacuum freeze dryers facilitate convenient long-term product storage. After undergoing the freeze-drying process, products can be rehydrated to their original form while maintaining their inherent chemical and biological properties.

features

6. Equipped with an industrial-grade embedded touchscreen and dedicated SH-HPSC-IV modular controller, the system offers outstanding stability, reliability and precise control performance.

7. The purpose-built LYO-CONTROL system stores multiple process recipes, with real-time process adjustment capabilities during drying to enhance process optimization efficiency.

10. An optional high-performance LYO-MEGA host computer system is available, which stores operational data, process curves and alarm logs for up to 10 years to enhance product traceability. It also simplifies real-time monitoring, operation and fault diagnosis.

8. Versatile manual and automatic control modes are available: manual mode supports process development, while automatic mode streamlines high-volume production runs.

9. Customizable user access levels and password protections enable structured, decentralized operational management.

1. Manufactured using specialized techniques, the shelf features high pressure resistance, excellent flatness and consistent temperature uniformity.

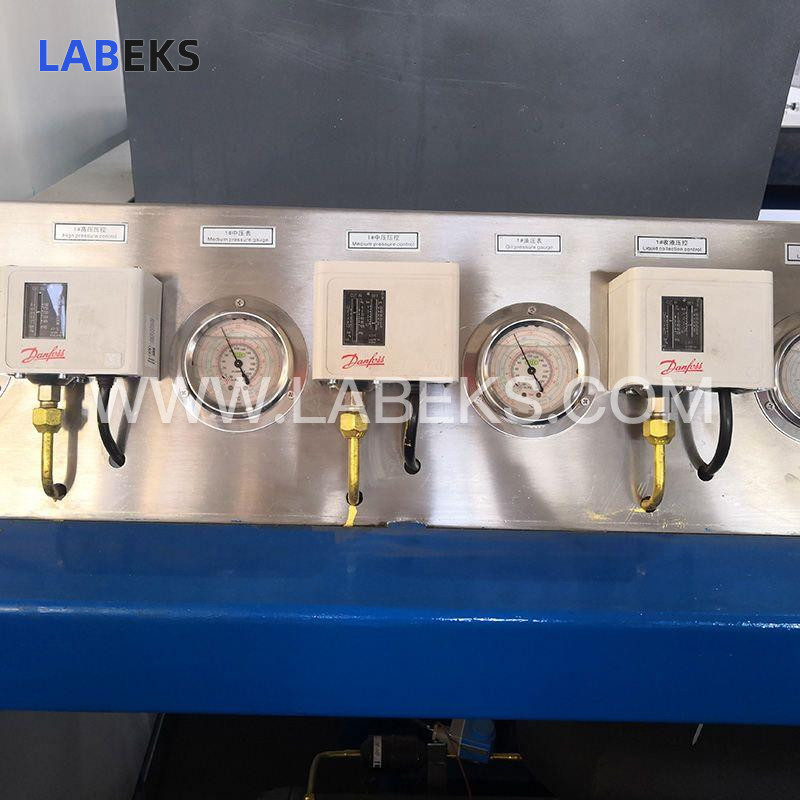

2. The high-performance mixed refrigerant boasts a low freezing point, high boiling point and exceptional heat exchange efficiency.

3. An optimized drying curve control algorithm regulates product heating rates and vacuum levels throughout the drying phase.

4. Specialized gas diversion design and control technology deliver robust water vapor capture capabilities and enhanced drying efficiency.

5. Vacuum levels are dynamically adjusted during operation to prevent foaming and splattering of sensitive materials, boosting overall drying efficiency.

11. Custom non-standard configurations are available to meet specific user requirements.

specifications

Model | GZL-10 |

|---|---|

Drying area (㎡) | 10.5 |

Input capacity (10mm thickness) (L) | 100 |

Shelf number (Layers) | 7+1 |

Shelf size (mm) | 990*1520 |

Shelf space (mm) | 80 |

Temperature range (°C) | -50~+80 |

Water vapor condensation (Kg/D) | ≥200 |

Cold trap temperature (°C) | ≤-75 |

Cooling mode | Water cooling |

Defrost mode | Water immersion |

Vacuum (Pa) | ≤5 |

Power (KW) | 50 |

Size (L*W*H) (mm) | 5000*2100*3600 |

Weight (kg) | 6500 |

why choose us

Premium Quality with CE & ISO

We conduct 100% performance testing on every unit, ensuring its stable operation and superior performance in your application.

24/7 Expert Technical Support

Our senior engineers are on standby 24/7, ready to provide expert solutions at any time to minimize your operational downtime.

20+ Years R&D & Production

Our deep technical expertise is your solid guarantee for professional and reliable OEM/ODM services.

Trusted in 80+ Countries

Industry leaders and research institutions in over 80 countries and regions rely on our equipment for stable operation.

True Manufacturer, Factory-Direct Price

Bypass the middlemen to get our factory pricing and speak directly with our core engineers.

Rapid & Reliable Delivery

Our extensive in-stock inventory provides a solid guarantee for rapid and reliable global delivery.

Our Factory

20 Years

58 Experts

20000 m²

7X24 Hours