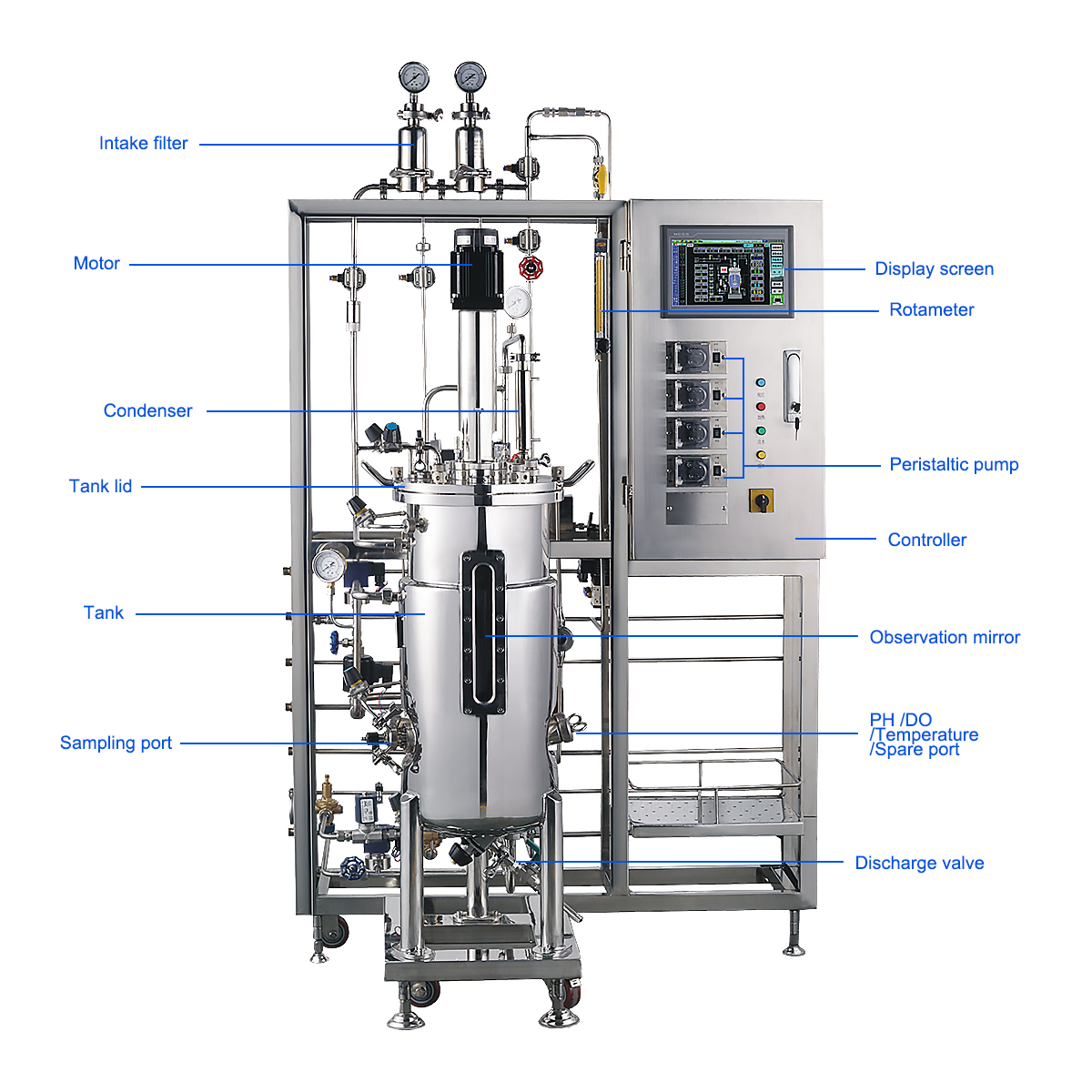

Stainless Steel Upper Mechanical Stirring Bioreactors for Microbial Culture with Precise Parameter Control

Tailored for yeast, enzyme, fungi, and bacteria culture test projects, the stainless steel upper mechanical stirring bioreactor features a simple structure, straightforward operation, and low failure rate, solidifying its status as a classic laboratory bioreactor model.

- modelLBR-XSJ Series

- brandLABEKS

- min. order1 pcs

- packageplywood case package

description

This shaft-coupled drive stainless steel bioreactor features an all-316L stainless steel tank body with no dead zones inside. It employs a direct-coupled mechanical stirring system driven from the top or bottom, boasting a simple structure and stable operation. Equipped with fermentation tank-specific sampling and discharge valves, as well as seed transfer pipelines, it also includes a large-view liquid level observation mirror and a 12V safety light. The system integrates temperature, pH, DO, defoaming, liquid level interface monitoring, along with an inoculation port, refilling port, and multiple spare ports. All welds are robust, neat, and aesthetically pleasing.

features

Process-based sectioned curve control is supported for tank medium temperature, stirring speed, pH, DO, and other key parameters.

Every parameter includes PID adjustment and process display, featuring set values, real-time readings, PID configurations, upper/lower limits, curve visualization, manual/automatic switching, and online adjustment capabilities.

Enables precise control over stirring speed, tank medium temperature, pH level, and DO concentration.

All core parameters (stirring speed, temperature, pH, DO) can be configured for automatic closed-loop control.

Configurable upper and lower limits for temperature, rotation speed, pH, and DO, with over-limit alarm functionality.

Equipped with high-liquid-level alarm and automatic refill, as well as excessive foam alarm and automatic defoamer dosing functions.

All alarm events are logged and retrievable for review.

Multi-year storage of historical parameter data and curves, with real-time curve restoration upon power resumption.

Offers replenishment metering functionality, supporting scheduled and quantitative feeding operations.

Features multiple interlock control modes, including speed-DO linkage, feeding-DO linkage, and feeding-pH linkage.

Provides real-time display, data logging, and analytical capabilities for the entire bioreactor operation process.

All detection and control loop parameters can be manually set and corrected online via the interface, with support for calibration of temperature, DO, pH sensors, and peristaltic pump flow rates. Operation is protected by a tiered password system, including operator and administrator access levels.

Automatically logs fermentation tank start-up time, shutdown time, power outage counts during automatic operation, outage duration, and power restoration time.

The integrated software system boasts adaptive and self-diagnostic capabilities.

specifications

Model | LBR-XSJ Series |

|---|---|

Volume | 5L/10L/20L/30L/50L/100L/200L/300L/500L/1000Loptional |

Diameter to height ratio | 1:2~3 |

Feeding volume | 70% |

Material | Stainless steel 304/316 |

Function | PH/DO/Foam/Temp control |

Pressure | 0.3Mpa |

Sterilization method | Automatic or manual sterilization |

Stirring system | Mechanical sealing system at thetop/bottom of the fermenter |

Stirring Speed | in the fermenter: 70~1000rpm±1% |

Temperature detection | Auto control (cooling water+5℃)~65℃±0.1℃ |

pH detection | 2.00-12.00±0.05pH |

DO detection | 0-150±3% |

why choose us

Premium Quality with CE & ISO

We conduct 100% performance testing on every unit, ensuring its stable operation and superior performance in your application.

24/7 Expert Technical Support

Our senior engineers are on standby 24/7, ready to provide expert solutions at any time to minimize your operational downtime.

20+ Years R&D & Production

Our deep technical expertise is your solid guarantee for professional and reliable OEM/ODM services.

Trusted in 80+ Countries

Industry leaders and research institutions in over 80 countries and regions rely on our equipment for stable operation.

True Manufacturer, Factory-Direct Price

Bypass the middlemen to get our factory pricing and speak directly with our core engineers.

Rapid & Reliable Delivery

Our extensive in-stock inventory provides a solid guarantee for rapid and reliable global delivery.

Our Factory

20 Years

58 Experts

20000 m²

7X24 Hours