10L-50L Explosion Proof Gas Scrubber for Laboratory Exhaust Absorption

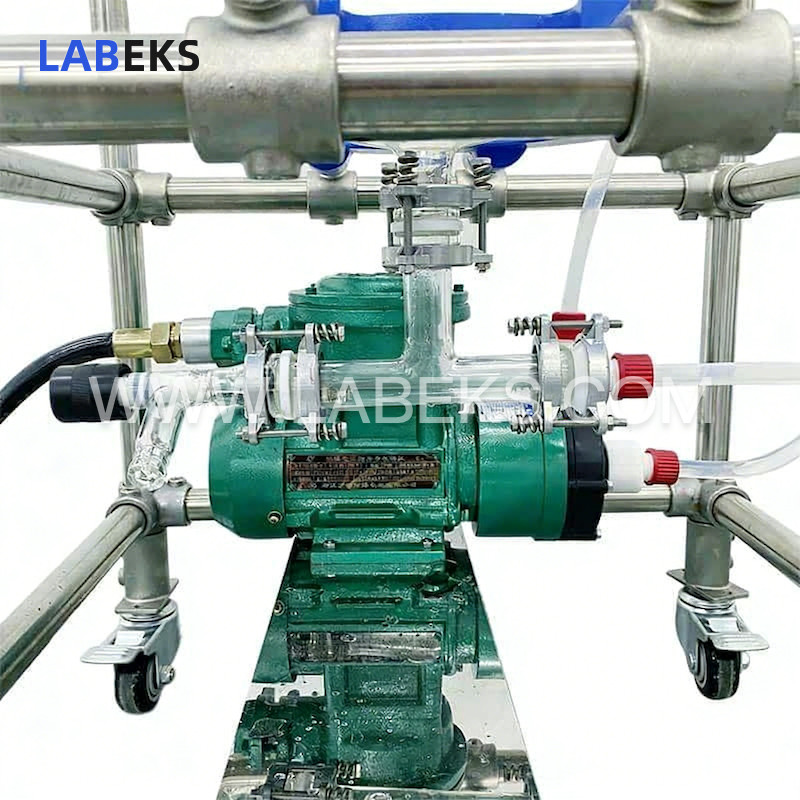

Designed for gas-liquid reactions and tail gas absorption, this explosion proof gas scrubber (10L-50L) fits perfectly in laboratory fume hoods, or can be used with mobile or desktop racks for flexible deployment. Key components include the main absorption tank, absorption tower, glass packing, circulation pump, cooling device, spray cap, and optional buffer tank.

- modelLUXH Series

- brandLABEKS

- min. order1 pcs

- packageplywood case package

description

Our 10L-50L explosion proof gas scrubber is tailored for a wide range of laboratory air purification and exhaust treatment applications. During operation, exhaust gas enters the inlet of the round-bottom flask and travels upward through the absorption column. Scrubbing fluid is pumped from the round-bottom flask to the shower head adapter, then flows counter-current to the exhaust gas through the packed column, facilitating intense gas-liquid contact for effective purification. The system can be operated via positive pressure using a carrier gas like nitrogen, or connected to a vacuum source via the column adapter.

features

1. High-vacuum ball mill connections ensure excellent airtightness

2. Effective prevention of absorbent backflow

3. High-efficiency water spray system with superior spray performance

4. Integrated glass packing for enhanced gas-liquid interaction

Operating Principle

Once the circulation pump is activated, absorption liquid is pumped from the round-bottom flask through the condensing line to the shower head, then sprays downward from the tower cap through the absorption tower and returns to the absorption tank. As it passes through the glass packing-filled tower, the liquid comes into full contact with the incoming gas, ensuring thorough mixing and efficient absorption. For high-temperature exhaust gas, a condenser must be connected to cool the absorption liquid. This system supports both active absorption (using nitrogen as a carrier gas) and vacuum-driven gas flow through the device.

Precautions

The scrubbing liquid must be selected based on the properties of the gas to be purified and its impurities: for acidic impurities, alkaline detergents (e.g., sodium hydroxide solution) are typically used; for alkaline impurities, acidic detergents (e.g., chromic acid lotion) are suitable; for neutral impurities, oxidizing detergents (e.g., potassium permanganate solution) can be employed. When choosing a detergent, two critical criteria must be met:

① The solute in the detergent must chemically react with the impurity gas, converting it into a precipitate or soluble substance, or the solvent must fully dissolve the impurity gas to achieve effective removal.

② The target gas (main gas) must have low solubility in the detergent and not be significantly absorbed by it. For example, when purifying chlorine gas containing hydrogen chloride, saturated brine is ideal: hydrogen chloride dissolves readily in the brine, while chlorine has low solubility. For carbon dioxide containing hydrogen chloride, concentrated sodium bicarbonate solution works well, as hydrogen chloride reacts fully with sodium bicarbonate, but carbon dioxide does not react with the solution and has low solubility. Using sodium carbonate solution is not advisable, as carbon dioxide will react with it to form sodium bicarbonate, resulting in unintended absorption of the target gas.

specifications

Model | LUXH-10 | LUXH -20 | LUXH-30 | LUXH-50 |

|---|---|---|---|---|

Washing cylinder capacity | 10L | 20L | 30L | 50L |

Number of openings in the kettle | 5 ports | |||

Connection method | Ball mill connection | |||

Circulating pump | Optional explosion-proof andanti-corrosion fluoroplastic material | |||

Quick release fixture | 304 stainless steel | |||

Filling method | Glass, stainless steel or other materialpacking | |||

Flange gasket | Tetrafluoro | |||

Flow rate | 86L/min | |||

Controller | 150W Optional explosion-proof | |||

Condenser | Standard configuration | |||

Vacuum | 0.098Mpa, the vacuum degree of thematching vacuum pump is required to reach 0.1MPpa | |||

Move method | With brake, universal caster | |||

Power supply | 220V/50Hz | |||

why choose us

Premium Quality with CE & ISO

We conduct 100% performance testing on every unit, ensuring its stable operation and superior performance in your application.

24/7 Expert Technical Support

Our senior engineers are on standby 24/7, ready to provide expert solutions at any time to minimize your operational downtime.

20+ Years R&D & Production

Our deep technical expertise is your solid guarantee for professional and reliable OEM/ODM services.

Trusted in 80+ Countries

Industry leaders and research institutions in over 80 countries and regions rely on our equipment for stable operation.

True Manufacturer, Factory-Direct Price

Bypass the middlemen to get our factory pricing and speak directly with our core engineers.

Rapid & Reliable Delivery

Our extensive in-stock inventory provides a solid guarantee for rapid and reliable global delivery.

Our Factory

20 Years

58 Experts

20000 m²

7X24 Hours