1L-5L Explosion Proof Rotary Evaporator for Solvent Recovery & Heat-Sensitive Samples

Ideal for optimizing concentration, crystallization, drying, separation and solvent recovery processes, the explosion-proof rotary evaporator serves as a critical instrument in pharmaceutical, chemical and biopharmaceutical sectors.

- modelLRE-201EX/LRE-301EX/LRE-501EX

- brandLABEKS

- min. order1 pcs

- packageplywood case package

description

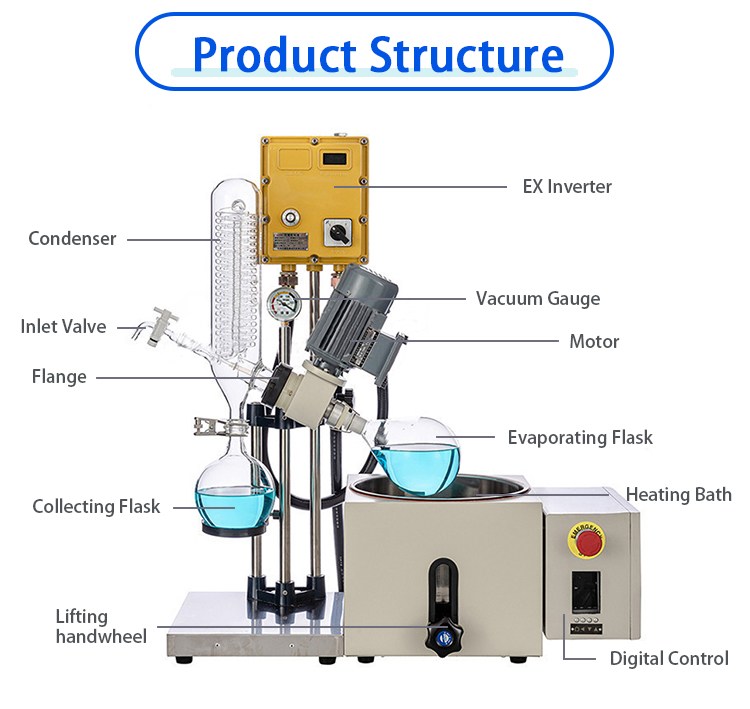

Primarily deployed for concentration, crystallization, drying, separation and solvent recovery within pharmaceutical, chemical and biopharmaceutical sectors, the explosion-proof rotary evaporator operates on the following principle: under vacuum, the rotating flask is heated at a constant speed, causing the material to spread into a large-area film on the flask wall for efficient evaporation. Solvent vapor is then cooled via a high-performance glass condenser and collected in the receiving flask, significantly boosting evaporation efficiency. This system is particularly well-suited for concentrating and purifying heat-sensitive biological products prone to decomposition and denaturation at elevated temperatures.

features

1. Comprehensive explosion-proof protection is integrated across the system, including explosion-proof aluminum enclosures for the variable frequency speed control module and control panel, as well as explosion-proof tubing for cable routing.

2. Variable frequency speed control with an explosion-proof switch is included, and a precision-adjustment knob allows for accurate speed regulation, with real-time revolution count displayed.

3. A combined sealing system of polytetrafluoroethylene and fluororubber ensures consistent maintenance of high vacuum levels.

4. The integrated vertical condenser features a double-layer serpentine coil design, guaranteeing high solvent recovery rates.

5. All material-contacting components are constructed from high borosilicate glass (expansion coefficient 3.3) and polytetrafluoroethylene, ensuring stable performance and excellent chemical inertness with processed materials.

6. The main support frame is fabricated from aluminum alloy with cold-plate anti-corrosion coating for superior corrosion resistance, while the bath vessel is made of stainless steel, delivering a compact, durable and aesthetically polished structure.

7. A pointer-type vacuum pressure gauge provides real-time vacuum level readings for clear monitoring.

8. The piston-type feeding valve is equipped with an extended PTFE tube, enabling continuous material feeding into the evaporation flask under vacuum conditions for operational convenience.

9. The constant temperature bath features digital temperature display, paired with a K-type sensor and stainless steel probe for rapid and accurate temperature transmission.

10. The bath vessel can be raised via a hand wheel, ensuring straightforward and user-friendly operation.

specifications

Model | LRE-201EX | LRE-301EX | LRE-501EX |

|---|---|---|---|

Voltage/Frequency | 220V/50HZ | 220V/50HZ | 220V/50HZ |

Whole power | 1040W | 2040W | 2040W |

Rotary power | EX40W | EX40W | EX40W |

Heating power | 1000W | 2000W | 2000W |

Vacuum degree | 0.0098Mpa | 0.0098Mpa | 0.0098Mpa |

Rotary flask volume | eggplant shape 1L,Φ131mm/24# standard port | 3L,Φ195mm/Φ50flangeport | 5L,Φ230mm/Φ50flangeport |

Receiving flask volume | round shape 1L,Φ131mm/35# ball mill port | 2L,Φ166mm/35# ball mill port | 3L,Φ195mm/上35# ball mill port,down with DN20 screw port |

Rotary speed | 0-120rpm/min | 0-120rpm/min | 0-120rpm/min |

Temp.cotrolling range | room temperature-180℃ | room temperature -180℃ | room temperature -180℃ |

Temp. accuracy | ±1℃ | ±1℃ | ±1℃ |

Flask lifting distance | 200mm | 200mm | 200mm |

Condenser size | Φ85*430H(mm) ,down with 35# ball mill port | Φ100*530H(mm) ,down with 35# ball mill port | Φ100*530H(mm) ,down with 35# ball mill port |

Condensation area | 0.17㎡ | 0.26㎡ | 0.26㎡ |

Charging valve | 19# standard plug valve,feed nozzle (Pagoda-shape connectors), outer diameter 10mm | 19# standard plug valve,feed nozzle (Pagoda-shape connectors), outer diameter 10mm | 19# standard plug valve,feed nozzle (Pagoda-shape connectors), outer diameter 10mm |

Vacuum suction nozzle | Pagoda-shape connectors, outer diameter 10mm | Pagoda-shape connectors, outer diameter 10mm | Pagoda-shape connectors, outer diameter 10mm |

Condensing coil in and out circuation nozzle | Pagoda-shape connectors, outer diameter 12mm | Pagoda-shape connectors, outer diameter 12mm | Pagoda-shape connectors, outer diameter 12mm |

Baiting valve | / | / | Side discharging nozzle (pagoda-shape connectors), outerdiameter 15mm, 200 from the floor |

Pot bravery size | Φ245*140H(mm) about 6.6L,5.5kg | Φ265*160H(mm) about 8.8L,7.3kg | Φ280*170H(mm) about 10.4L, 13kg |

Overall dimensions (W*L*H) | 750*360*1060mm | 790*360*1090mm | 790*360*1090mm |

Net weight | 32kg | 33kg | 34kg |

Packing dimensions | 900*620*470mm, 0.29m³ | 1090*690*490mm0.37m³ | 1090*690*490mm, 0.37m³ |

Packing weight | 49kg | 50kg | 51kg |

why choose us

Premium Quality with CE & ISO

We conduct 100% performance testing on every unit, ensuring its stable operation and superior performance in your application.

24/7 Expert Technical Support

Our senior engineers are on standby 24/7, ready to provide expert solutions at any time to minimize your operational downtime.

20+ Years R&D & Production

Our deep technical expertise is your solid guarantee for professional and reliable OEM/ODM services.

Trusted in 80+ Countries

Industry leaders and research institutions in over 80 countries and regions rely on our equipment for stable operation.

True Manufacturer, Factory-Direct Price

Bypass the middlemen to get our factory pricing and speak directly with our core engineers.

Rapid & Reliable Delivery

Our extensive in-stock inventory provides a solid guarantee for rapid and reliable global delivery.

Our Factory

20 Years

58 Experts

20000 m²

7X24 Hours