20L Rotary Evaporator with High Solvent Recovery & Vacuum Stability

Ideal for chemical laboratories, the rotary evaporator enables efficient, gentle solvent removal from samples through controlled evaporation, ensuring reliable and precise sample processing results.

- modelLRE-20

- brandLABEKS

- min. order1 pcs

- packageplywood case package

description

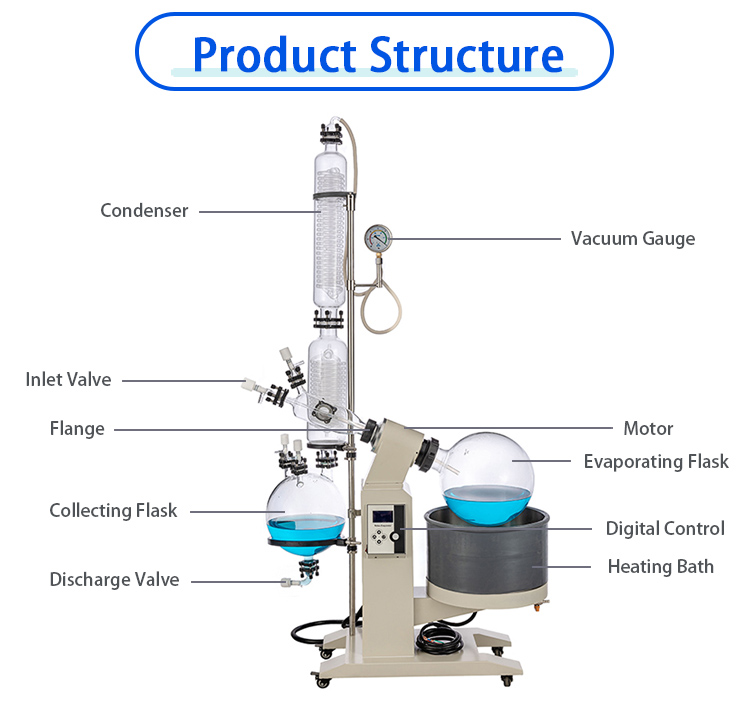

The rotary evaporator utilizes stepless speed regulation to rotate the glass flask at a constant speed, forming a uniform, large-area liquid film on the flask’s inner wall. Under vacuum conditions, the rotating flask is uniformly heated by an intelligent constant-temperature water bath to enable high-speed evaporation. Vapors are then efficiently cooled by the glass condenser and collected in the receiving flask.

features

1. Over-temperature safety protection: The unit automatically powers off when the actual temperature exceeds the set temperature by 5℃.

2. Anti-dry heating protection: The machine shuts down automatically if the water level in the heating pot drops below the heating tube.

3. Power-off restart protection: After a sudden power outage and subsequent restoration, the machine will automatically stop heating.

4. All glass components are crafted from high borosilicate glass (GG-17), offering superior high-temperature and corrosion resistance.

5. Main body constructed with stainless steel + aluminum alloy, featuring a rational structure optimized for material stress distribution.

6. Sealing system combines imported fluororubber and Teflon for two-way sealing, delivering long-term corrosion resistance, extended service life, and sustained high vacuum levels.

7. Vertical three-tier serpentine coil condenser paired with primary + secondary dual condensers to guarantee high solvent recovery rates.

8. DC brushless motor ensures stable rotation, spark-free operation, and gradual torque increase for smooth performance.

9. Electric bath lifting system incorporates a deceleration motor, ensuring exceptionally smooth lifting and lowering processes.

10. Bath tank made of premium 304 stainless steel for corrosion resistance and durability; outer silicone layer enhances safety during high-temperature operation.

11. Oil-filled vacuum pressure gauge with anti-vibration properties displays real-time vacuum levels.

12. Check valve control enables continuous discharge, allowing vacuum state switching while the machine is in operation.

13. All valves adopt the latest single-handle wheel design, providing excellent sealing and simplified, intuitive operation.

14. Supports continuous feeding via a valve-type feeding valve equipped with a PTFE tube assembly.

15. Collection bottle features a discharge valve, simplifying collection and discharge of evaporated extracts.

16. Full LCD screen offers dual digital readouts for temperature and rotation speed; bath pot constant temperature control uses a PT100 sensor for fast, accurate temperature transmission.

17. Microcomputer-controlled power switch for reliable and straightforward operation management.

specifications

Model | LRE-20 |

|---|---|

Voltage/Frequency | 220V/50HZ |

Whole power | 5100W |

Rotary power | 60W 1/5 |

Lifting power | 40W 1/12.5 |

Heating power | 5000W |

Vacuum degree | 0.0095Mpa |

Rotary flask volume | 20L,Φ355mm/Φ95Flangeport |

Receiving flask volume | 10L,Φ280mm/ upperwithΦ60 *Φ35 flange port*2*down with Φ50 flange port |

Rotary speed | 0-120rpm/min |

Temp.cotrolling range | room temperature -180℃ |

Temp. accuracy | ±1℃ |

Flask lifting distance | 150mm |

Condenser size | The main condensor Φ100*700H(mm)upper with Φ60 flange port * down with Φ80flange portThe assisted condensor Φ160*530H(mm)upper with Φ80 flange port* down withΦ60 flange port*side with Φ60 flange port |

Condensation area | 0.94(0.46+0.48)㎡ |

Air guide bottle | Left with Φ35 flange,upper with Φ35flange,side withΦ60 flange,right with Φ60 flange |

Charging valve | Φ35 flange,glass+PTFE valve,feed nozzle (pagoda-shape connectors) outer diameter 12mm |

Multi-function port | Φ35 flange,glass+PTFE valve, glass nozzle (pagoda-shape connectors)outer diameter 12mm |

Vacuum suction nozzle | Φ60 flange glass exhaustor, suction nozzle (pagoda-shapeconnectors), outer diameter 10mm |

Condensing coil in and out circuation nozzle | Pagoda-shape connectors, outer diameter 16mm |

Vent valve | Φ35 flange port*2, glass+PTFE valve, vent nozzle(pagoda-shape connectors), outer diameter 12mm |

Baiting valve | Φ50 flange port, side discharging nozzle(pagoda-shapeconnectors), outer diameter 20mm, 210mm from the floor |

Pot bravery size | Φ450*560H(mm) about 41L |

Overall dimensions (W*L*H) | 1210*610*2170mm |

Net weight | 78kg |

Packing dimensions | 1050*530*1210 ,0.68m³ |

Packing weight | 110kg |

why choose us

Premium Quality with CE & ISO

We conduct 100% performance testing on every unit, ensuring its stable operation and superior performance in your application.

24/7 Expert Technical Support

Our senior engineers are on standby 24/7, ready to provide expert solutions at any time to minimize your operational downtime.

20+ Years R&D & Production

Our deep technical expertise is your solid guarantee for professional and reliable OEM/ODM services.

Trusted in 80+ Countries

Industry leaders and research institutions in over 80 countries and regions rely on our equipment for stable operation.

True Manufacturer, Factory-Direct Price

Bypass the middlemen to get our factory pricing and speak directly with our core engineers.

Rapid & Reliable Delivery

Our extensive in-stock inventory provides a solid guarantee for rapid and reliable global delivery.

Our Factory

20 Years

58 Experts

20000 m²

7X24 Hours